DIY Guide: Google Pixel 4a Vibration Motor Replacement

Duration: 45 minutes

Steps: 42 Steps

This repair guide comes courtesy of the talented folks at Salvation Repair, and it’s not an official Google blessing. Curious to see our other guides? Take a peek here!

Heads up! The Pixel 4a’s display panel is delicately designed, so handle with care!

This handy repair guide comes straight from the brainiacs at Salvation Repair and isn’t given the thumbs up by Google. Discover more about what we do here. Ready to tackle the replacement of your vibration motor on a Google Pixel 4a? Just a heads up—the Pixel 4a’s display panel is a bit on the delicate side. So, be extra cautious and pay attention to the warnings while opening it up, especially if you’re planning to reuse the screen!

Step 1

– Time to get started! Insert a SIM eject tool, or if you don’t have one, a straightened paper clip or a small tool will do the trick, into the SIM tray hole.

– Gently press the tool straight into the hole until the SIM card tray pops out.

– Now, carefully remove the SIM card tray – you’re making great progress! If you need help, you can always schedule a repair

Step 2

Hey there, look out for that orange ribbon cable under the lower-right corner of the screen. It’s a little sensitive, so be gentle with your opening pick! Just slide it in as far as you need to loosen things up. You got this! And if you need a hand, you can always schedule a repair.

Alright, time to get this screen up! It’s like a little puzzle, so read these steps carefully before you start popping things open. And remember, if you need a helping hand, you can always schedule a repair.

– Let’s get started by checking out the two seams on the edge of your phone:

– Before you dive in, take a look at these important areas on the screen:

– Screen seam: This is the line that separates the screen from the rest of the phone. This is where you’ll want to carefully pry open your device.

– Frame seam: This is where the plastic frame meets the back cover, held together with screws. Be sure to avoid prying at this seam to prevent any damage.

– Screen flex cable: When using your opening pick, be careful not to insert it too deeply, as this can damage the cable and cause more problems.

– Adhesive perimeter: To avoid damaging the OLED panel, make sure to angle your pick and stay within this narrow perimeter when prying. If you need help, you can always schedule a repair

Step 3

Hey there, you can also use a hairdryer, heat gun, or a hot plate if you’ve got one! But be careful not to get too hot-headed. The display and battery are pretty sensitive to heat, so keep that in mind! If you need help, you can always schedule a repair.

– Time to get this repair started! Apply a heated iOpener to the right edge of the display for about a minute. This will help loosen the adhesive, making the next steps a breeze. If you need help, you can always schedule a repair

Tools Used

Step 4

If your screen is sporting a serious crack, slapping on a layer of clear packing tape might just do the trick to help that suction cup stick. Not feeling the suction cup? No worries! A strong tape can also lend a hand. And if you’re in a pinch, a little superglue on the suction cup might just save the day for that broken display.

– Get that suction cup close to the right edge of the screen, right next to that seam.

– Now, give that suction cup a good, strong lift! We’re going to gently pry it open.

– Take that opening pick and slide it carefully into that screen seam. Don’t go too far, just a tiny bit, maybe 1mm. No need to get wild with it!

Step 5

Hold up! If you feel the pick hitting a bump, it’s likely you’re bumping against the edge of the OLED panel. Just angle the pick a bit and try again. You’ve got this! If you need help, you can always schedule a repair.

Get ready to expertly insert that pick without a scratch on your precious OLED panel! Trust us, this little move is the perfect warm-up before diving into the adhesive slicing action.

– Slide the pick about 1 mm into the gap, then tilt it up at a fun angle.

– With that nifty tilt, gently nudge the pick into the gap for about 1/4 inch (6 mm). It should glide right under the OLED panel like it’s on a mission!

Step 6

Keep that pick to a cool 1/4 inch (6 mm) or less, or you might just give the screen’s flex cable a little too much love!

Step 7

Be careful when working under the bottom-right corner of the screen – there’s a delicate cable hiding out. If your opening pick catches on something, don’t force it. Instead, pull it out and try again with a slightly different angle. Remember to keep your pick angled downward and only insert it as far as necessary to loosen the adhesive, about 2 mm deep. If you need help, you can always schedule a repair

– Time to get fancy! Slide another opening pick into the right edge of your phone where you already started to create a gap. This helps keep your OLED panel happy and safe.

– Now, glide that pick around the bottom of the phone, like you’re giving it a little love tap! This cuts through the adhesive holding it together.

– Keep that pick in place along the bottom edge – we don’t want the adhesive sneaking back in!

Step 8

If the screen is being stubborn, try heating the left edge for about a minute and then give it another shot. If you need help, you can always schedule a repair

– Slide another opening pick into the bottom edge where you already see a gap, to avoid messing up the OLED panel.

– Use the pick to slice through the left edge of your phone.

– Keep the pick in place along the left edge, so the adhesive doesn’t sneak back into place.

Step 9

Take a peek at the earpiece speaker on the top edge of the screen – there’s a mesh covering it. If you’re missing a replacement mesh, be gentle so you don’t damage or misplace this tiny part.

Having trouble slicing through the screen? Try heating the top edge for about a minute and then give it another shot. If you need help, you can always schedule a repair

– Aye aye, Captain! Let’s slide that pick around the top edge of your phone like a pro, so we can cut that adhesive. Just think, soon we’ll be conquering this repair together. If you need help, you can always schedule a repair.

Step 10

Hold your horses! The screen stays put for now.

– Now that you’ve cut around the phone’s perimeter, gently pry up the right edge of the screen – think of it like opening a book. Take your time and be careful.

– Use an opening pick to carefully slice through any remaining adhesive. If you need help, you can always schedule a repair

Step 11

Handle that ribbon cable with care—give it some love and keep the stress away!

– Lift the screen from the top edge and gently swing it over the bottom edge until it’s safely resting glass-side down. If you need help, you can always schedule a repair

Step 12

– Grab your trusty tweezers and carefully peel back the black tape protecting the screen connector bracket. It’s like unveiling a hidden treasure!

– If the tape’s still in tip-top shape, feel free to reuse it when you put everything back together. But if it’s looking a little rough, swap it out for a fresh piece of electrical tape.

Tools Used

Step 13

As you tackle this repair, keep an eye on each screw and make sure it finds its way back to its original home.

– Alright, let’s get this party started! Grab your trusty T3 Torx screwdriver and give those two little 2.1 mm screws holding the screen connector bracket in place a friendly twist. You’ve got this!

Step 15

– Time to get started! Use the tip of a spudger to carefully pry up and disconnect the screen flex cable – it’s like a little wake-up call for your device.

– Now, let’s get this connector back in place. To reattach press connectors like this one, line it up just right and gently press down on one side until you hear that satisfying click. Then, repeat the process on the other side. Remember, don’t press down on the middle, or you might end up with bent pins and a bigger problem on your hands. If you need help, you can always schedule a repair with the pros at Salvation Repair.

Tools Used

Step 16

As your device powers up post-reassembly, it’s going to run through a calibration dance for the screen. Just a heads up—keep your fingers off the screen during this part! Touching it could throw off the calibration and lead to some quirky touch issues.

Refer to the third photo to get your adhesives in the right spot – it’s a great reference point to ensure everything is lined up correctly. If you need help, you can always schedule a repair

– Let’s get started by removing the screen.

– Now it’s time to install a new screen:

– Check if your replacement screen comes with speaker mesh and top edge adhesive already installed – it’s a nice bonus if it does!

– If not, no worries! Follow this guide to apply the custom-cut adhesive and get your screen looking brand new.

– If your new screen does come with the adhesive pre-installed, you can skip this step – you won’t need the extra top edge adhesive.

– If it doesn’t come with the adhesive, remove the larger clear liner from the top edge adhesive and carefully apply it to the screen, making sure the larger cutout lines up perfectly with the speaker mesh. If you need help, you can always schedule a repair with Salvation Repair.

Step 17

– Grab your trusty T3 Torx driver and get ready to tackle the eight 4.3 mm screws holding the back cover snugly against the midframe. Let’s get that cover off and see what’s inside!

Step 18

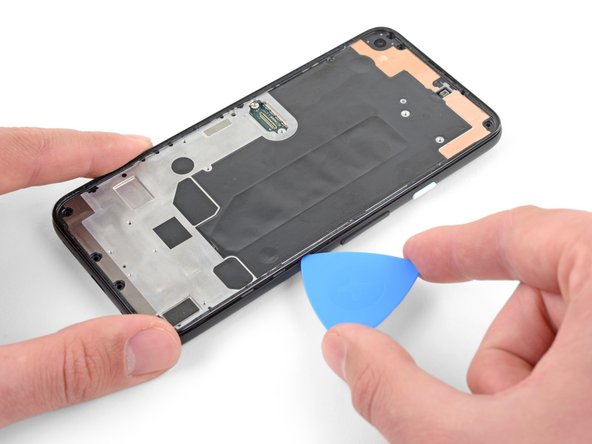

– Get ready to make a move! Slip that opening pick into the little gap between the midframe and the back cover.

– Now, gently glide the opening pick along the bottom edge of the phone to pop those pesky plastic clips loose that are holding the back cover in place.

Step 19

– Let’s get this back cover off! Gently slide the opening pick around the left edge of the phone to release those pesky plastic clips holding it on.

Step 20

– Now, let’s get this phone open! Slide the opening pick around the top and right edges of the phone to release the rest of the clips. It’s like giving your phone a little hug, but with a tool! Don’t worry, it’s totally normal for your phone to make a little popping sound as those clips release.

Step 21

– Let’s get this party started! Carefully swing the back cover from the bottom of the phone over the top and around the back. It’s like a graceful dance!

– Now, lay the back cover down on your work surface and gently place the midframe on top of it. Just a little rest, no need to get crazy and put any pressure on those ribbon cables, okay?

Step 22

– Alright, time to remove the motherboard bracket! Grab your trusty T3 Torx driver and give those seven screws a little spin. You’ll be working with three 2.9 mm-long black screws, three 2 mm-long screws, and one 4.1 mm-long screw.

– If you need help, you can always schedule a repair.

Step 23

– Gently use the tip of a spudger to pop off the motherboard bracket from the top-right and bottom-right corners of the motherboard. You’ve got this!

Tools Used

Step 24

– Grab those tweezers and carefully lift off the motherboard bracket. If you need help, you can always schedule a repair.

Tools Used

Step 25

– Time to get started! Use the flat end of a spudger to carefully pry up and disconnect the battery cable. If you need help, you can always schedule a repair

Tools Used

Step 26

– Now it’s time to get those flex cables disconnected – use the tip of a spudger to carefully release the two cables connecting the fingerprint sensor and buttons to the motherboard. If you need help, you can always schedule a repair

Tools Used

Step 28

– Grab your trusty spudger and gently pry away the headphone jack cable from the motherboard. You’ve got this!

Tools Used

Step 29

– Slide an opening pick beneath the headphone jack and give it a little twist to break free from the adhesive holding it to the midframe.

– Carefully take out the headphone jack.

Step 30

– Alrighty, it’s time to disconnect the front-facing camera! Gently use the flat end of a spudger to help remove it from the motherboard. If you need a little extra help, don’t hesitate to schedule a repair!

Tools Used

Step 31

– Time to get up close and personal with that front-facing camera! Use a trusty pair of tweezers to carefully remove it. If you need help, you can always schedule a repair

Tools Used

Step 32

– Grab your trusty T3 Torx driver and let’s get those two 4.1 mm screws out of the loudspeaker assembly! You’ve got this!

Step 33

Watch out for that delicate white membrane next to the speaker! If you plan to keep it in action, give it a gentle poke and be careful not to puncture it.

– Slide the spudger under the loudspeaker assembly – it’s time to get this repair started!

– Gently flip the loudspeaker assembly over, so it’s resting lightly on top of the battery. If you need help, you can always schedule a repair

Tools Used

Step 34

– Now it’s time to carefully disconnect the antenna flex cable from the loudspeaker assembly – simply use the tip of a spudger to gently pry it loose. If you need help, you can always schedule a repair

Tools Used

Step 35

Be gentle with that white membrane on either side of the speaker – you’ll want to keep it intact if you’re planning to reuse it. If you need help, you can always schedule a repair

– Alright, let’s gently lift that loudspeaker assembly right off the tape holding it down. We’re gonna give it a little wiggle and freedom.

– Now, carefully remove the loudspeaker assembly. You got this!

Step 36

– Grab your spudger and gently pop the loudspeaker cable off the motherboard. If you need help, you can always schedule a repair

Tools Used

Step 37

– Grab your trusty T3 Torx driver and get ready to remove the three screws holding the motherboard in place:

– Look for two 2.9 mm-long black screws – they’re the first to go

– Next, find the one 2.1 mm-long screw and carefully remove it. If you need help, you can always schedule a repair

Step 38

– Alright, let’s get that earpiece speaker uncovered! Grab your opening pick and gently use the corner to peel up the tape that’s holding it down. It’s like a little treasure hunt for your speaker! If you need help, you can always schedule a repair.

Step 39

– Grab your trusty tweezers and give that tape covering the earpiece speaker a good yank! It’s time to say goodbye to that tape. Don’t worry about putting it back on during reassembly, it’s all good!

Tools Used

Step 40

– Slide the spudger’s tip under the motherboard’s bottom edge and gently lift it just enough to grab on with your fingers. Don’t be shy, you’ve got this!

Tools Used

Step 42

The vibration motor is stuck in place with a bit of adhesive, but don’t worry, it’s easy to remove. If you need help, you can always schedule a repair

– Time to get a little handy! Use your trusty tweezers to carefully pry the vibration motor straight off the midframe.

– Now, simply remove the vibration motor – you’re making great progress! If you need help, you can always schedule a repair

Tools Used